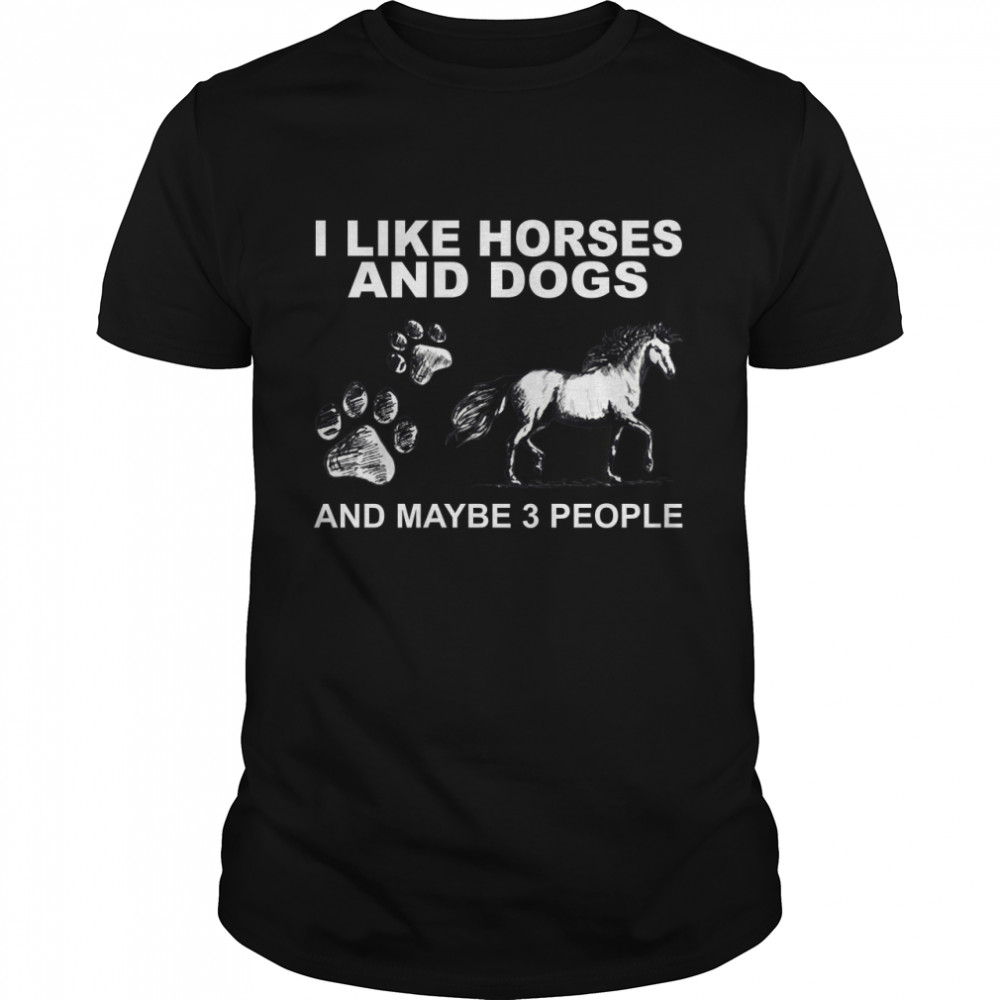

Meta Band Fuel Since 1981 Seek And Destroy Rock shirt

$27.99 Original price was: $27.99.$22.99Current price is: $22.99.

Meta Band Fuel Since 1981 Seek And Destroy Rock shirt, hoodie, sweater, longsleeve and ladies t-shirt

You Can See More Product: https://kingteeshop.com/product-category/trending/

1. Order Processing Time

-

Order Handling: Orders are typically processed within 2–5 business days after successful payment.

-

Made-to-Order Production: Since many of our items are printed on demand, production may take a little longer during high-volume periods (e.g., holidays).

-

Orders placed on weekends or public holidays will be processed on the next business day.

2. Shipping Time Estimates

We ship worldwide. Estimated delivery times (after processing) are:

| Region | Estimated Delivery Time |

|---|---|

| United States | 5–10 business days |

| Canada | 7–12 business days |

| United Kingdom | 7–12 business days |

| Australia | 7–14 business days |

| Europe | 7–15 business days |

| Rest of World | 10–20 business days |

🕐 Note: Delivery times are estimates and may vary due to customs delays, carrier disruptions, or other unforeseen circumstances.

3. Shipping Rates

Shipping costs are calculated at checkout and vary depending on:

-

Shipping destination

-

Weight and quantity of items ordered

-

Current shipping carrier rates

We may offer free or discounted shipping promotions from time to time — be sure to check banners or newsletters for updates.

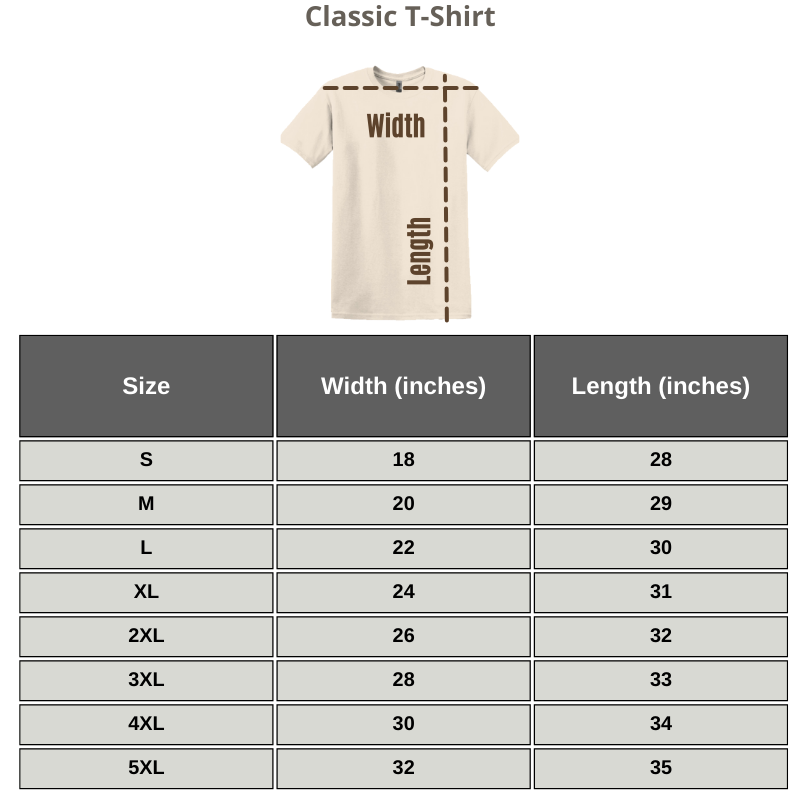

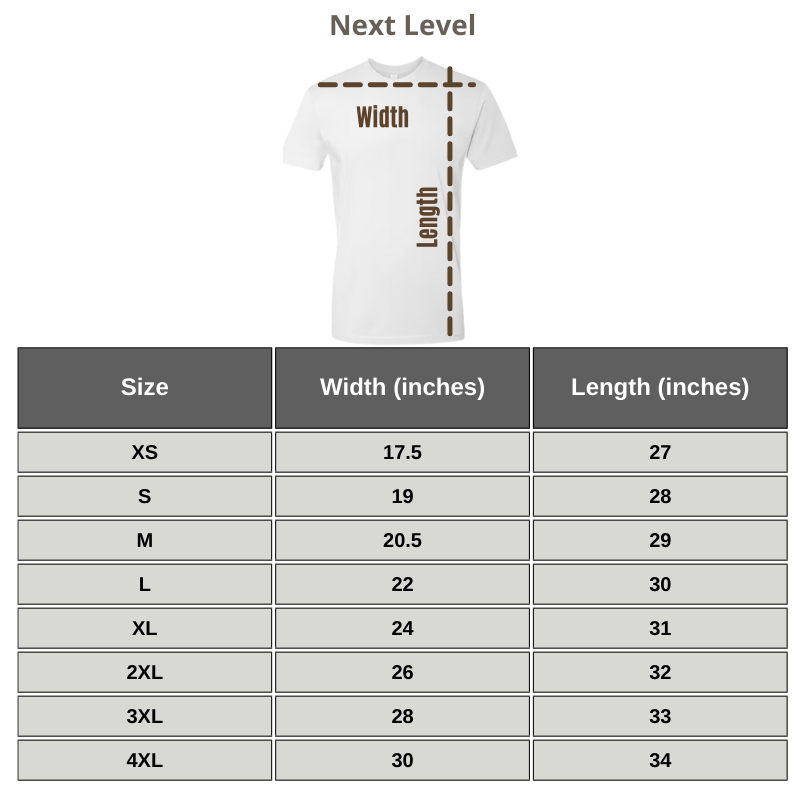

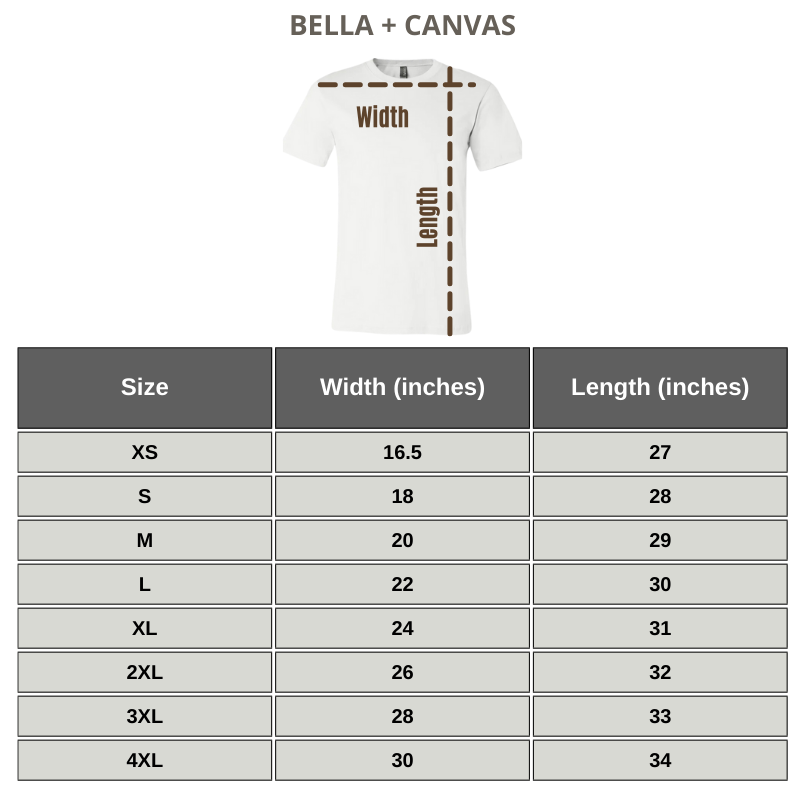

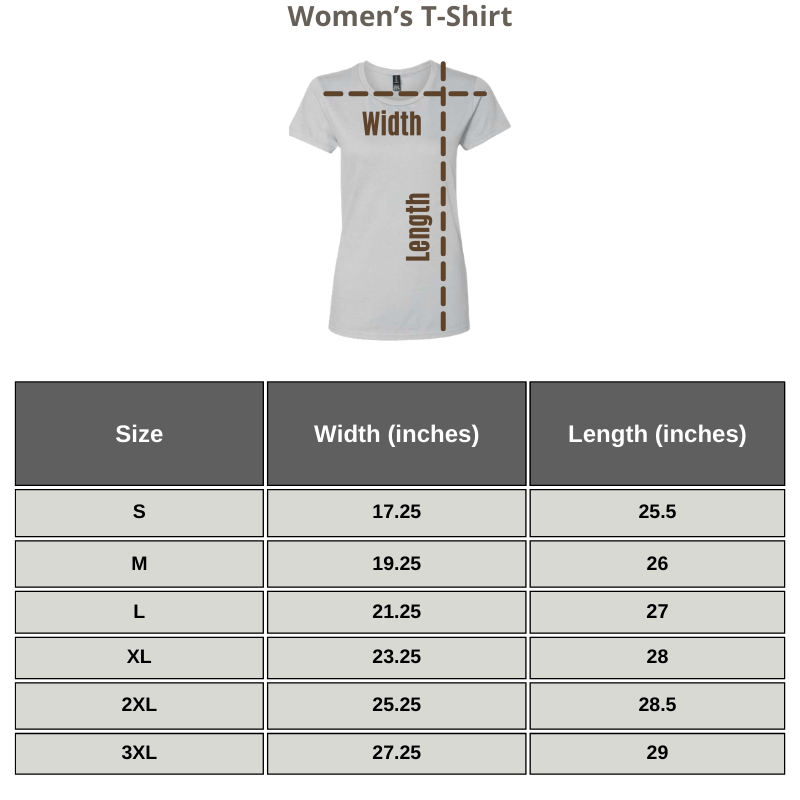

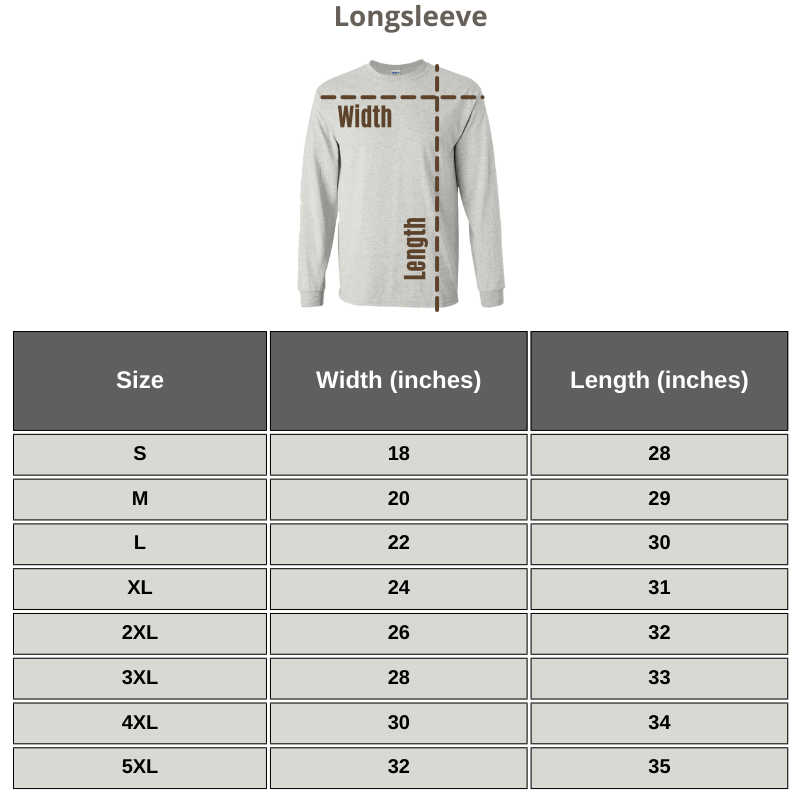

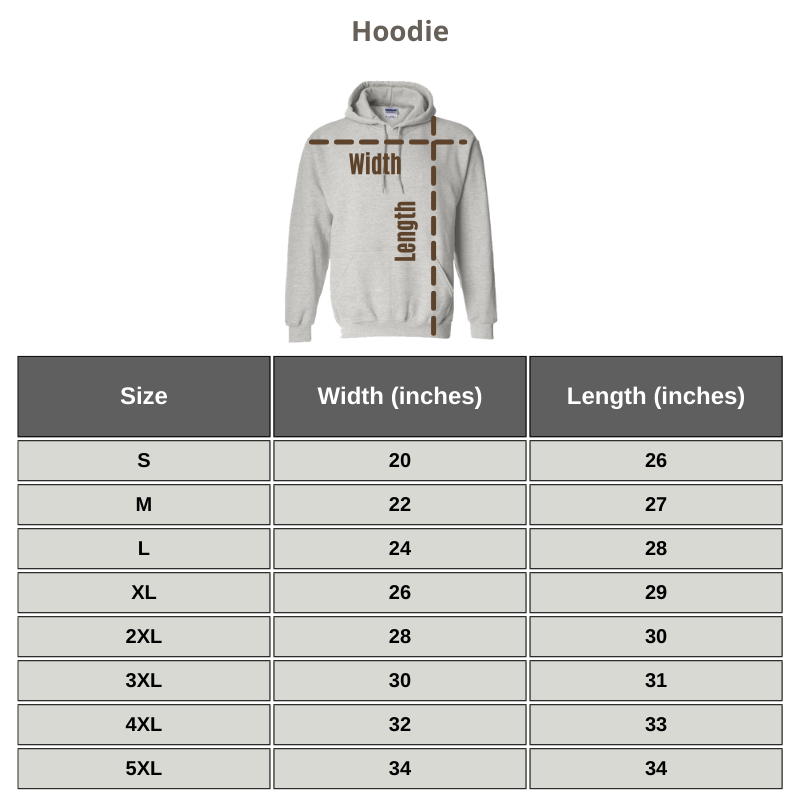

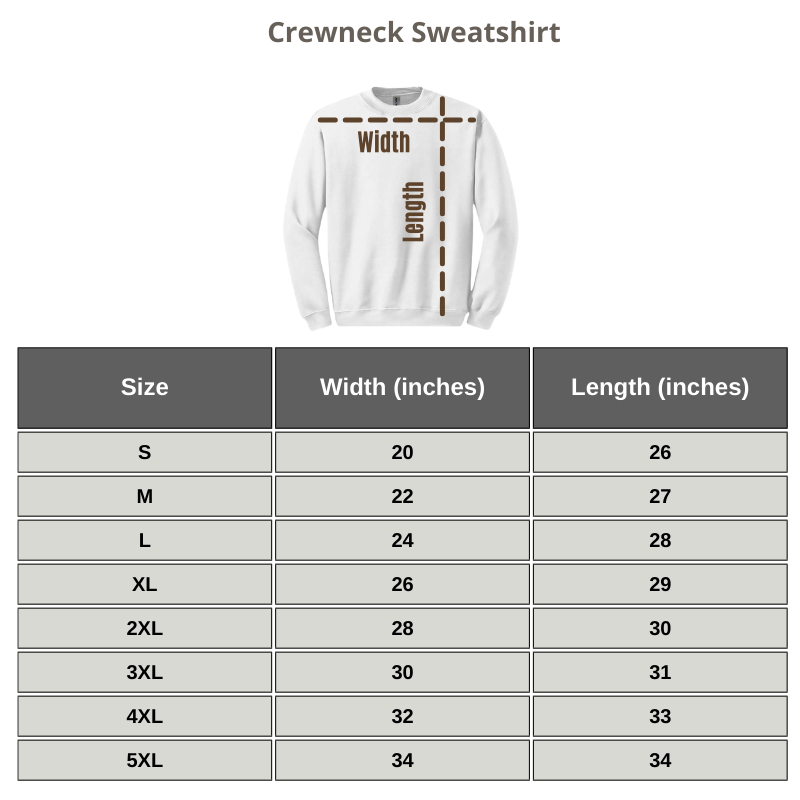

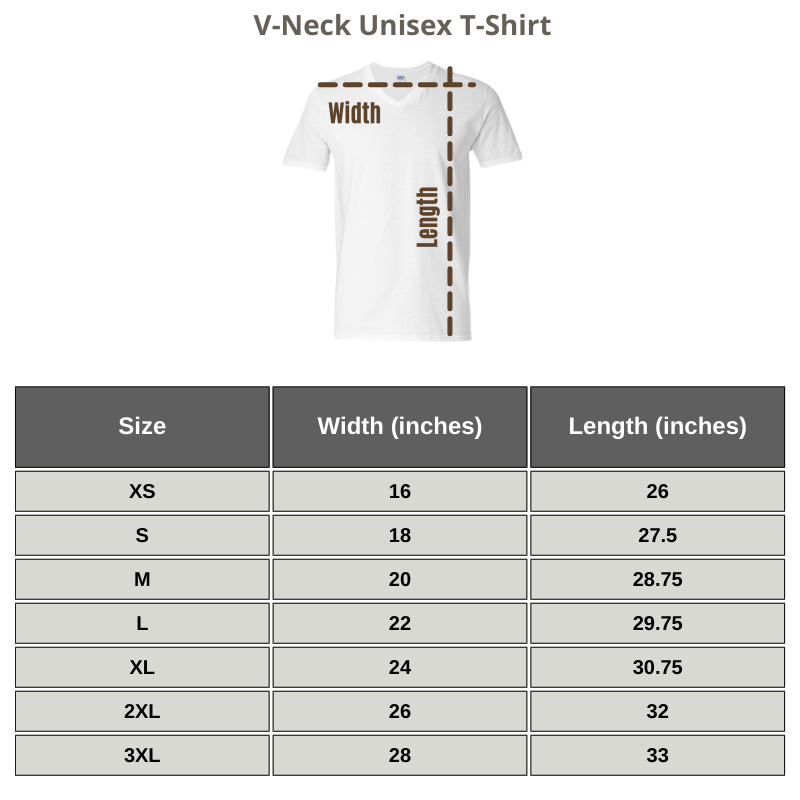

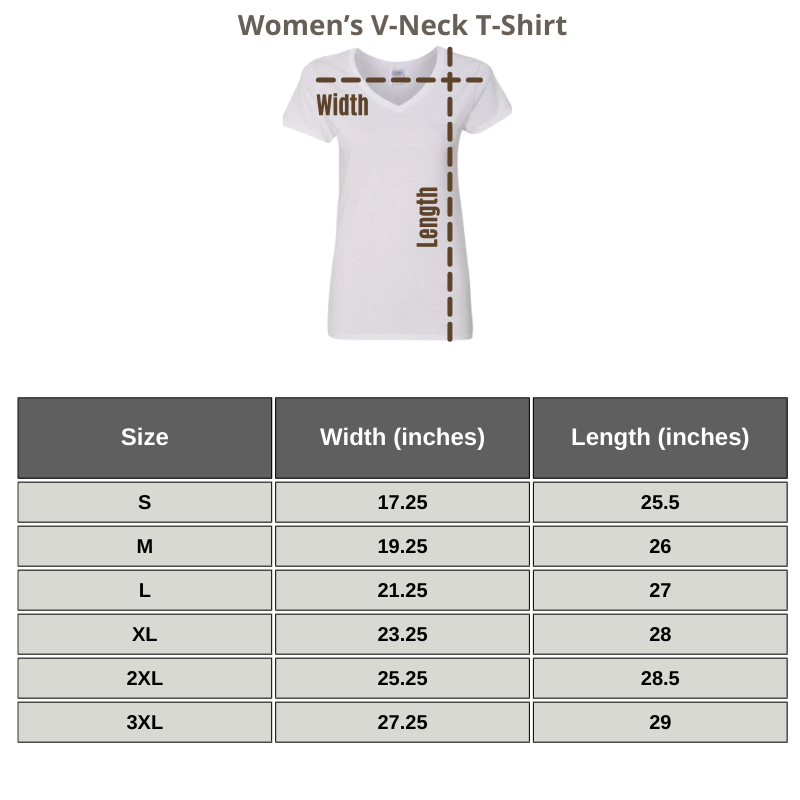

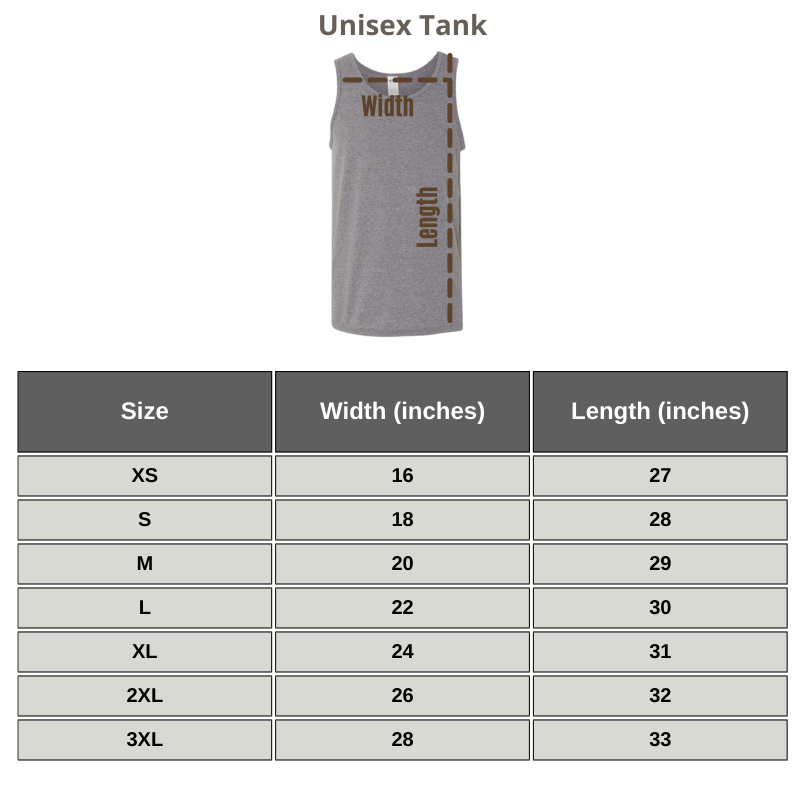

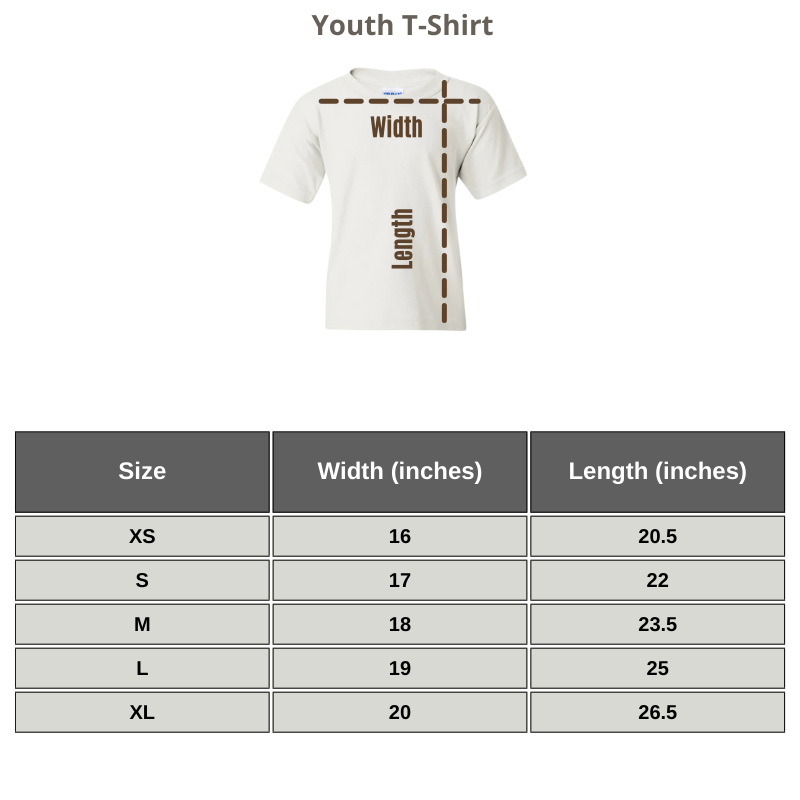

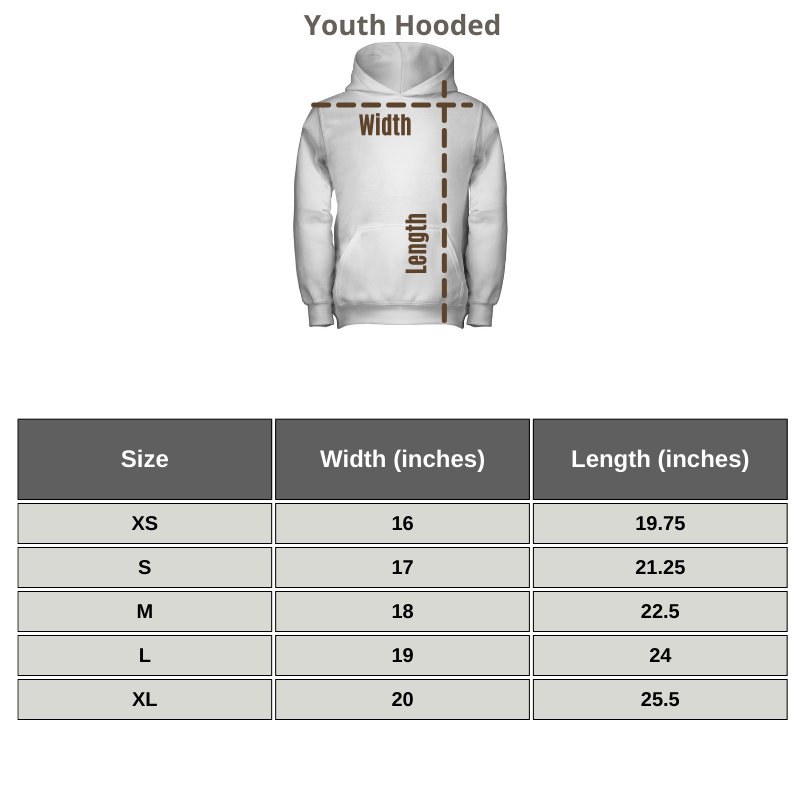

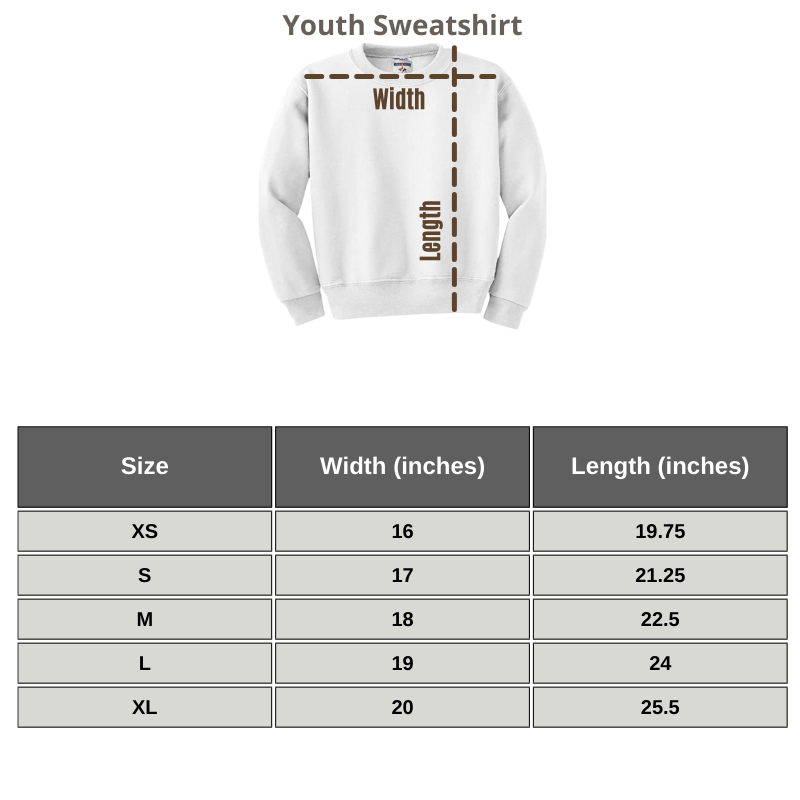

SIZING GUIDE

Reviews

There are no reviews yet.